What is Arachne?

It is the new perimeter generator, developed by Ultimaker for Cura, and implemented also in Slic3r-based programs like Super Slicer and Prusa Slicer.

What advantages does it have over classic perimeter generators?

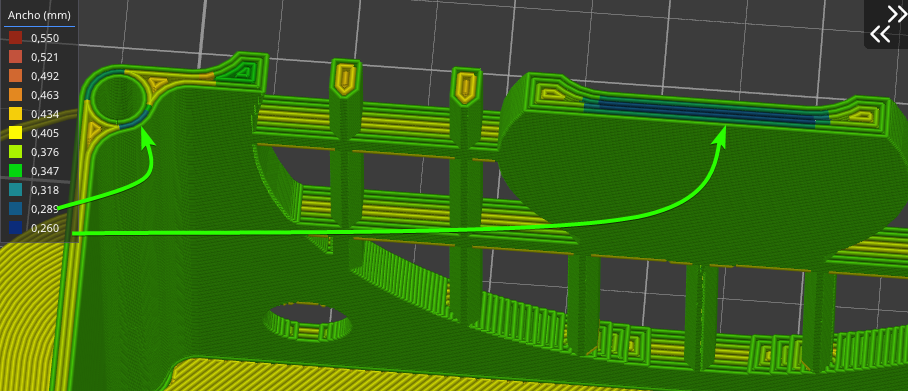

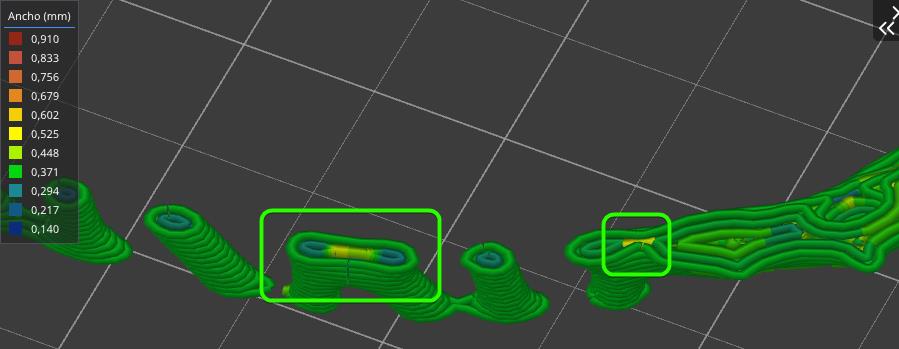

Until now, the perimeter generators used a static extrusion width, linked to the nozzle width, this generated in some areas "Holes", which could later be filled with additional passes if we activate "fill holes", these passes do have a variable width depending on the space left.

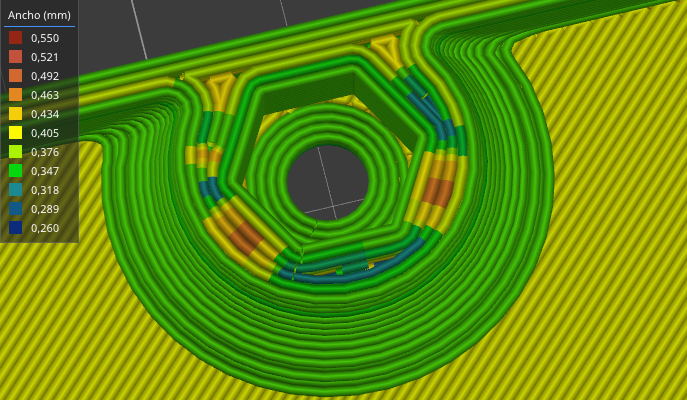

This solution is fine, it works perfectly, but Arachne brings us something better: variable width perimeters. In this way, the extrusion width is not only linked to the nozzle diameter, but is also adjusted according to the geometry of the area to be filled, avoiding gaps and additional passes in many cases. Not only does it give more precise results, but we will also print faster.

It should be noted that it may have a trade-off, by using variable width it is possible that we may have more flow changes in some prints, and this may worsen the results in bowden 3D printers and/or with poorly calibrated "Pressure advance".

Type of parts in which it can be an advantage:

- Cases and housings.

Until now, when making a box or housing with thin walls, such as the electronics box for our 3D printers, we had to use thicknesses that are multiples of the extrusion width we want to use. For example, if we use an extrusion width of 0.5, we can use thicknesses of 1, 2, and 3mm so that these walls are made with 2, 4, and 6 passes respectively. If we wanted to use a thickness of 2.1mm for example, I would make 4 passes of 0.5, and an additional pass of 0.1 to fill the gap, which would be a waste of time.

Arachne will spread that 0.1 between adjacent perimeters, avoiding the need for the additional pass.

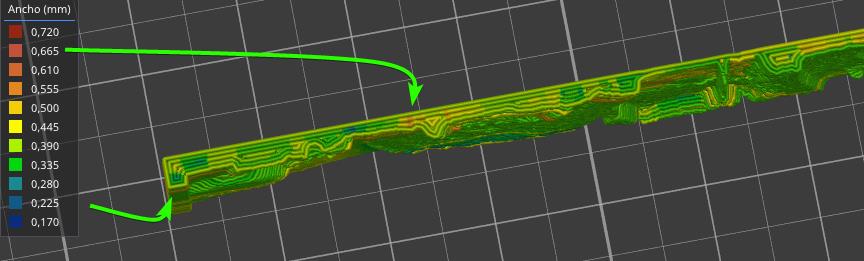

- Propellers and thin pieces with variable diameters.

With this type of parts we have the same problem as with boxes and casings, aggravated by the fact that we cannot choose the thicknesses freely, since they will depend on the geometry of the part, in some areas we will have excessively thin hollow fillings and in other areas excessively thick, which can also mean a worse surface finish, with this engine these problems are largely avoided.

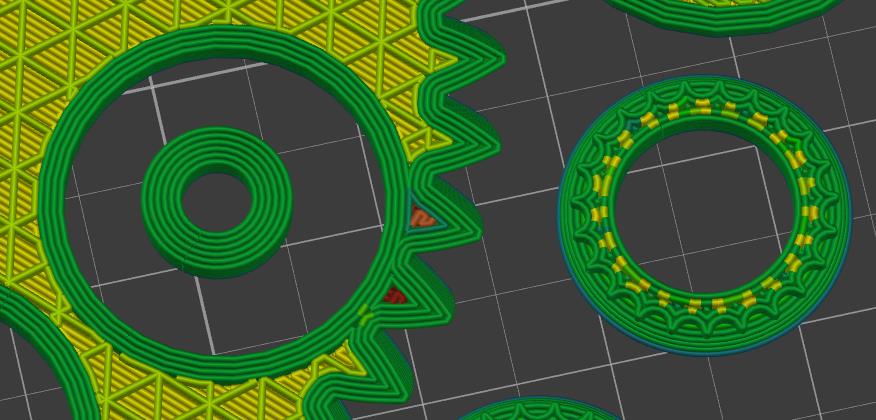

- Lithographs.

Here we will notice a huge improvement, as the filling of holes is more precise, and we will also need fewer passes, so we will have sharper and cleaner results.

- Highly detailed models.

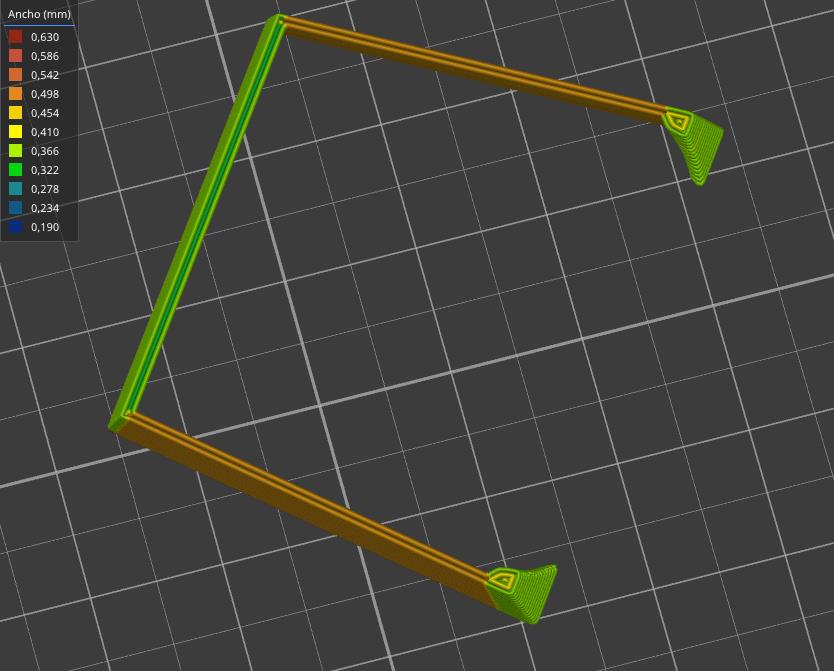

This motor is more precise in calculating the amount of material to be deposited in each extrusion, and it also rounds each additional perimeter, so our printer will make smoother and more precise movements that have an impact on the final finish. - Very angular mechanical parts.

The outer perimeter will run along the outer surface of the part as before, but the inner perimeters will be rounded, smoothing the part's shell internally and avoiding the accumulation of stresses that occur at the corners.

Do you want to try it?

Super Slicer, our favorite slicing program includes it as of version 2.5.59. Cura includes it by default as of version 5.

For the curious:

Arachne, in Greco-Roman mythology was a weaver who boasted of being more skilled than the goddess Athena, which has its equivalent in the Roman Minerva, goddess of craftsmanship and wisdom, a very appropriate name, don't you think?

1 Comment(s)

Thank you for sharing such valuable insights on <a href="https://contusion.co/write-for-us/">Write For Us Health</a>. Your article has truly inspired me to take better care of myself.

Leave a Comment