The power supply is one of the key components in our 3D printer. Sizing it well is a critical factor in the stability and durability of our printer.

Differences between Nominal power and Working power

This is perhaps the critical and most important point of this article since the power supplies are defined by their nominal power or their nominal intensity. But this value is not the value to which we must make them work. Nor is the actual consumption that the 3D printer will have.

A 400W source, for example, can work at 400W for short periods of time, but it should not do so for prolonged intervals.

Likewise, its consumption will depend on the load at each time. For example, if this same 400W source is used in a printer without a heatedbed, it will probably never consume more than 70W, it will therefore work well below its nominal value.

How to calculate the working power of our printer?

This is a relatively simple task, although it should not be taken lightly.

We must add together the consumption of each of its components. Something that at first seems simple, but it may not be.

The heated bed, the element with the highest consumption

20x20 heated beds usually have a consumption of about 90-100W approximately, as we go up in size, temperature and heated bed material we can find hot beds of up to 400W.

To know this power we can do two things:

- Consult the manufacturer or distributor specifications. It is the simplest, but also less accurate, as sometimes there may be differences between one bed or another, and between different manufacturing items. These differences are usually slight, but can be especially important in high-powered beds.

- Measure the power through the electrical resistance. We recommend to do it once the cables are welded, so that we also make sure we have correctly welded the wiring.Therefore, to know the power we need to know the voltage and resistance. The voltage will be 12 or 24 as we have selected the electronics and the resistance must be measured.

How to measure the resistance of the heated bed?

The multimeter cannot be used directly to take this measurement, since the electrical resistance of the heated beds is very low, and the resistance value of the multimeter itself will affect the measurement. To take this measure we can use two methods mainly:

- Method "Voltmeter - Ammeter":

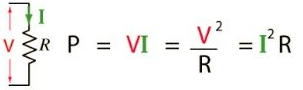

It consists of measuring the voltage and electrical intensity, so that using the above formula we can easily measure the resistance

R = V/I

In a bed that gives us 10A to 12V, we have a resistance of 1.2 ohms. - Measure the resistance of the multimeter and subtract it from the one given by the reading.

This method is unreliable, but it will help us to make a quick check, you can measure the resistance value of the multimeter with the terminals touching and subtract it from the values you have taken from the heated bed.

The heater of the hotend

It can be measured exactly like the heated bed, its power is usually between 30W and 50W, with 40W being the most common.

Motors

Depending on the calibration of the controllers it is common that they consume between 0.5 and 1A each motor. In a normal printer there are 5 motors, so 0.75A * 12V * 5pcs = we have 45W.

Ventiladores, LCD y demás accesorios

Although they usually have little power individually, as a whole we can easily reach 10W, a small consumption but that must be added to the equation along with the other components.

We already have the total power consumption

In the case of a "normal" 3D printer it will be:

- 100W for heated bed

- 40W for hotend

- 45W for motors y drivers

- 10W electronics in general

We have a total power consumption of 205W.

Security factor

Having done the previous sum with a result of 205W we may be tempted to use a 200W source, or a 240W source, but this would be a mistake. Since it would take us to a damaged source in a matter of minutes, hours or days. Why would this happen to us? For not having taken into account any safety factor.

How to calculate the safety factor?

We are not going to go into excessively technical aspects, since this is something very important in the industry, we are simply going to comment on some points to consider:

- Time of continuous use.

Are we going to size our printer for prints of many hours? Generally yes, since impressions usually take hours and even days to complete. - Type of load.

It is not the same to feed a stable resistance, that a more complex load, 3D printers have many oscillations in the load, turn on and off the bed abruptly, and have components with inductive loads such as motors, so that the power supplies suffer more with this type of charges than with a simple LED. - Critical application.

Does something happen if the power supply fails? A military or medical equipment cannot fail, there are lives at stake, but a 3D printer must not fail either, although there are no lives at stake. Often we find tight deadlines to meet, so it is not convenient to skimp because it can cause losses and delays, being this is more important for 3D printers designed for professional use. - Room temperature.

El calor es uno de los factores que más castiga a la electrónica, la zona en la que tengamos instalada la fuente de alimentación influye en su vida útil, generalmente se instalan en un lateral manteniendo la refrigeración y evitando que estén sometidas al calor generado por la cama caliente.

Generally manufacturers of power supplies recommend a safety factor of 0.8. Or what is the same, that the working power does not exceed at any time 80% of the nominal value of the power supply, we recommend using a slightly greater factor so that our source lasts for years and years, even working at high temperatures .

0.6 is the value we recommend.

In the previous calculation we have obtained a working power of 205W, divided by 0.6, it gives us a power of 341.6W, so we will choose the power supply following the calculated power.

Other factors to consider

Dedicated fan

It is a component that greatly lengthens the life of the power supply, prevents overheating when the usage time is high, and usually goes by default in power supplies of power greater than 300W.

In a 3D impesora we consider the use of a fan to be practically essential, since the use time is usually prolonged. If the source does not incorporate it, we can add a DC fan of the same voltage as the source and a printed piece to hold it.

Location

It is advisable to place the source on one side or area of the printer where it is removed from the heat produced by the hot bed, in addition to having good ventilation. It is advisable as much as possible to avoid "all-in-one" boxes with poor ventilation, since temperatures can rise greatly inside if they are not well ventilated or the fans deteriorate over time. Make sure the ventilation is correct at all times.

8 Comment(s)

Hola buenas tardes. Tengo una fuente switching de 24v 10a la puedo utilizar en alguna parte de la impresora 3d? o la descarto directamente y utilizo otra?\r\nEspero su respuesta muchas gracias.

Este tipo de fuente puede ir genial para una impresora 3D sin cama caliente y con una cama caliente pequeña de baja potencia.

Que fuente necesito para una impresora 3d tamaño de cama caliente 30x30 y un solo extrusor?

Depende de la potencia de la cama, en ese tamaño suelen ser muy potentes, por lo que necesitarás una de las fuentes mas grandes, algunas camas pueden llegar a necesitar 2 fuentes de alimentación en paralelo o una fuente de 600w o superior.

Puedo usar una fuente 24v 10a 360w para una ender 3 comun?

Depende del consumo que tengas con la impresora, el modelo 24v 15a 360w es apropiado para la mayoría de impresoras con cama caliente que no tengan una potencia muy alta, si la cama es muy muy potente mejor 24v 20a 480w o similar.

Tengo una impresora anet a8 y la fuente que trae es de 12 volts, ¿ puedo utilizar una de 24 volts?

No, ya que se quemarían los componentes que no estén preparados para 24v, necesitas cambiar estos componentes antes de hacer el cambio. Generalmente, son la placa principal, ventiladores y resistencias.

hola estoy cotizando una impresora 3d pero el consumo de la fuente segun los calculos es de 510w y tiene que se de 12v estaria bien eso?

Para impresoras 3D de gran potencia, como la que nos indicas, es mucho mejor usar una fuente de 24v, ya que tendrás menos perdidas por efecto joule y mejor rendimiento.

hola tengo una cama caliente mk2a de 300mm que fuente recomiendas

Te recomiendo medir la resistencia, para estar seguro de la potencia, ya que por el tamaño no se puede saber con seguridad.

Hola, puedo utilizar la fuente de alimentacion de 24v 15A y 360w en una ender 3 pro? La original tambien es de 24v y 15A asi que lo unico que no encajaría serian los 360w. Eso es un problema? Espero vuestra respuesta, muchas gracias

Si, sería una fuente equivalente, ya que tendrán el mismo amperaje nominal.

Buenas, tengo una Anet A8, esta stock, ¿Que fuente me recomendaría?

Una con el mismo voltaje, pero más intensidad que la que lleve de serie.

Leave a Comment