When we start in 3D printing we usually pay a lot of attention to eye-catching components, such as the extruder or the board. But until we delve a little deeper we do not begin to pay attention to other vital and fundamental elements, such as the case of fans and their role in cooling specific parts of our 3D printer.

According to its function:

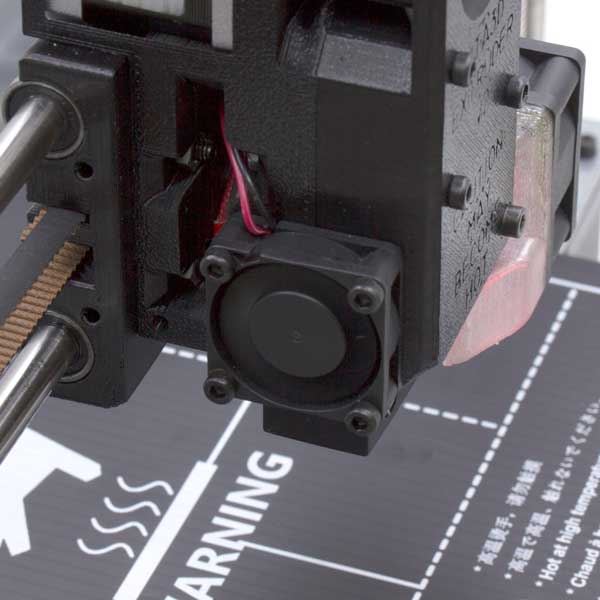

- Layer fan:

It is the best known, it is responsible for cooling the piece during printing to favor the solidification of the material and prevent deformities caused by excess heat.

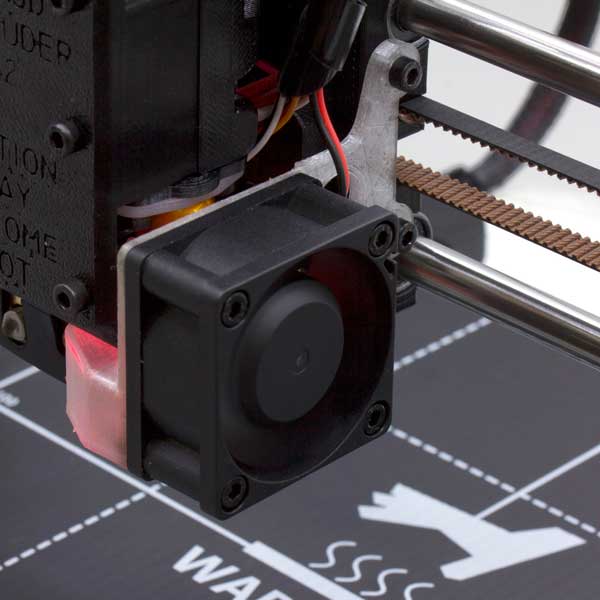

- Hotend fan:

It usually goes unnoticed until it stops working properly, since its function is essential in modern extruders, when it fails, the extruder gets stuck, since its function is to keep the cold zone of the extruder cold enough, and prevent the filament melts prematurely.

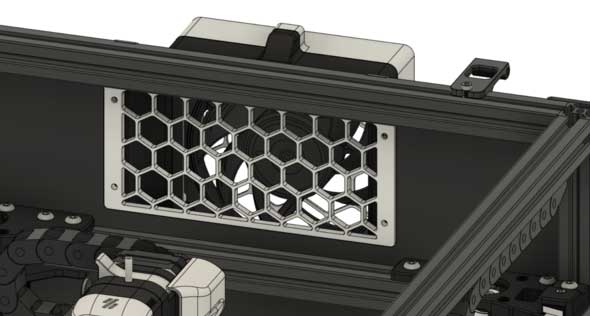

- Electronics fan:

This is optional, although from our point of view highly recommended.

Todos los elementos de la electrónica producen calor, y cuanto más potente es la impresora y sus componentes más calor producen, este calor hay que evacuarlo de alguna forma, y ahí entra el ventilador de la electrónica mantiene todos los componentes electrónicos en una temperatura óptima y evita problemas de sobrecalentamiento así como fallos prematuros, alargando la vida útil de nuestra impresora y sus elementos.

- Power supply fan:

Also optional and the great ignored as it usually comes standard on high power power supplies.

It has exactly the same function as the electronics fan, but applied to the power supply where we also find many elements that produce heat during operation.

- Chamber fan:

In some closed 3D printers we find a fan/extractor that extracts a small amount of air and makes it pass through a filter, its function is to prevent harmful odors and particles from leaving 3D printers that work materials at high temperatures.

- Other less common fans:

- Fan for motors, are sometimes used in giant 3D printers, since they are configured with motors that produce a lot of heat.

- Fan for liquid cooling systems.

- Etc.

According to type of airflow:

- Axial or Helical Fan:

They are the most common type of fan, the air passes in a direction parallel to its axis. They can move large amounts of air where resistance to airflow is low. They are recommended for applications where the distance that the air will travel is low, as is the case with our 3D printers.

In 3D printing they are commonly used in these applications:- Fan of the power supply and/or electronics, since they are the ones that provide the best air flow at the lowest cost.

- Hotend heatsink fan, for the same reason, simple, efficient and easy to mount.

- Layer fan, when designed to maximize airflow, with air ducts that do not overly close the air outlet and therefore do not require high pressure.

- Blower fans:

It is made up of two parts, the casing, which is shaped like a snail or volute, and the impeller that it has has a certain number of blades, the air inlet is in the center and the outlet is in a corner. They have worse performance than Axial fans, but they are suitable in many applications where, due to technical needs, they are preferred over axial ones. In 3D printing they are commonly used in these situations:- Layer fan designed with a very localized air outlet, where the small air outlet is favorable to direct the air flow.

- Very small heatsinks, where the aim is to concentrate the air outlet as much as possible.

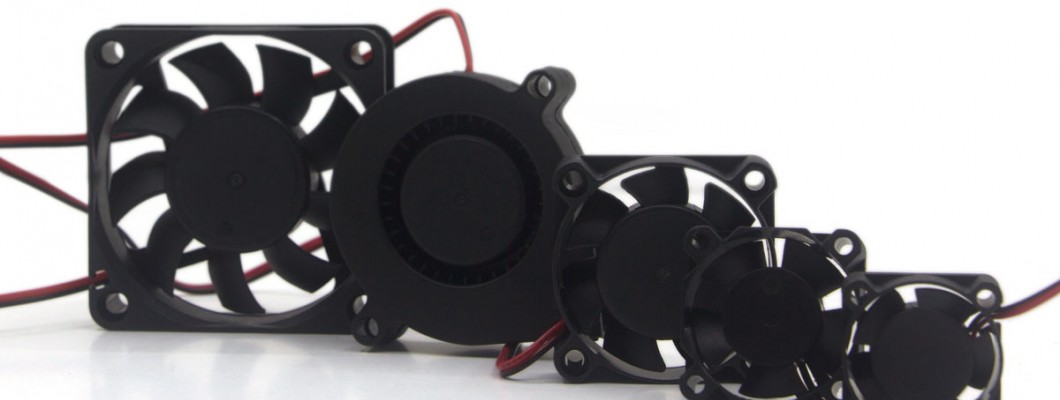

According to size:

Occasionally we want a very small printer, like the VORON V0.1, and this requires making everything as compact as possible, including the fans, and this leads us to use fans as small as the 3007, at 30x30x7mm in size.

In other cases we want to have the greatest possible airflow, it is common to find 6020, 6015 fans, and even some larger ones such as 8020, in larger 3D printers to cool electronic components.

In most situations we find intermediate situations where we have to find a "compromise solution", for this reason for example we use the 4020 fan in our layer fan, and the 3010 for the hotend. Other designs often use a slightly thinner and slightly larger 5015 for the layer fan, and the 4010 or 2510 for the hotend. Using very large sizes offers advantages of airflow, pressure and reliability, but they are also heavier and bulkier.

- Nomenclature, the size is usually indicated in four digits, the first two refer to the external size of the fan, and the last two refer to the thickness, all in millimeters. For example, the 4020 forms a prism with a side of 40mm and a height of 20mm. Axial fans usually have a square shape, while centrifugal fans usually have three rounded corners.

According to movement:

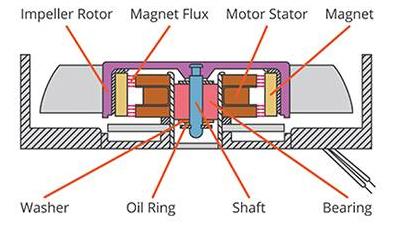

- Sleeve bearing, it is the simplest and most common model, since it is cheap to produce and meets the needs of many applications.

The shaft is made up of two parts made of a porous and lubricated material, so that while it rotates the natural wear and tear of the shaft keeps it lubricated.

As a disadvantage, it has that during its useful life these surfaces wear out and dry, producing gaps that generate noise and reduce performance.

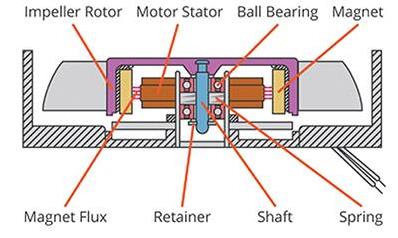

- Ball bearing, as a disadvantage, it has that during its useful life these surfaces wear out and dry, producing gaps that generate noise and reduce performance.

For a long time, the best fans have been of this type.

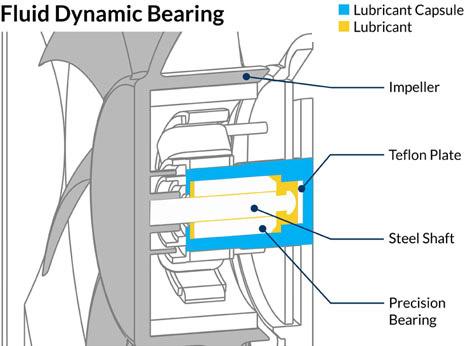

- Hydraulic, it is an evolution of the bush bearing, in which both parts do not touch directly, a fluid is circulated between them. In this way we get the best of the two previous types: we avoid the noise of mechanical bearings, obtaining a similar performance.

- Other types such as magnetic levitation bearings, which are not currently used in 3D printing.

Remarkable features:

Air flow

It is the flow of the fan, the mass of air that it can displace in a unit of time.

It is expressed in m3/h (1,7 m3/h = 1 CFM).

Fan speed

Indicates the speed at which it will turn at nominal voltage, it is indicated in RPM, Revolutions Per Minute.

Useful life

All fans have an indicated useful life, there are factors that can shorten and lengthen it. As what interests us is to maximize the useful life, we can give these tips in this regard:

- Use quality fans, these will heat up less and last longer.

- Larger fans have a longer life as they generally spin at a lower number of revolutions.

- Activate them only when necessary. Some boards, increasingly allow to control several fans, the SKR2, for example, allows to control up to 3 fans.

- Keep them in a good state of maintenance, removing the "lint" and dust that may remain on their blades, also if it makes noise you can remove the sticker to put a drop of oil on the axis and keep it better lubricated.

Lifespan is measured in hours, a 35,000 hour fan will be able to run for up to 4 years if kept in good condition.

Voltage

- Each fan has the nominal voltage indicated, they should never be connected to a higher voltage as they will heat up and burn, however if they can be connected to a lower voltage, they will work at a lower speed.

A "trick" that can be done in 12V printers, for electronics, is to install a 24V fan without regulation and larger than what would be necessary, for example a 6020, this fan when turning at a relatively low speed will hardly sound , it will have a very high life, and it can provide us with more than enough ventilation.

Nominal current

- It is the current that it will receive connected to its nominal voltage and turning at maximum revolutions, it helps us to calculate its energy consumption, or size the mosfet that regulates it, in 3D printing fans of 0.1A or less are normally used that are easily regulated with any mosfet, but if you want to connect 2 or more fans to a regulated output, it is convenient to check the specifications of the board and the fans to avoid damaging the board.

Note on qualities

- Nowadays we can find everything from poor quality ball bearings, built with cheap materials, which offer poor performance and short lifespan, and well-functioning bushing fans, with good construction that will perfectly cover any need. If we want a reliable solution, it is very important to see where we buy the fans and if they have a brand, a well-known brand fan in a trusted specialized store may be the most recommended option.

This small component of our 3D printers has given enough of itself, we didn't want to go into other issues such as positive and negative pressure, or analyze the values of its technical sheet. If you have any questions about these fans, we encourage you to ask them in the comments!

Leave a Comment