Posted By

26 Aug

0 Comment(s)

13675 View(s)

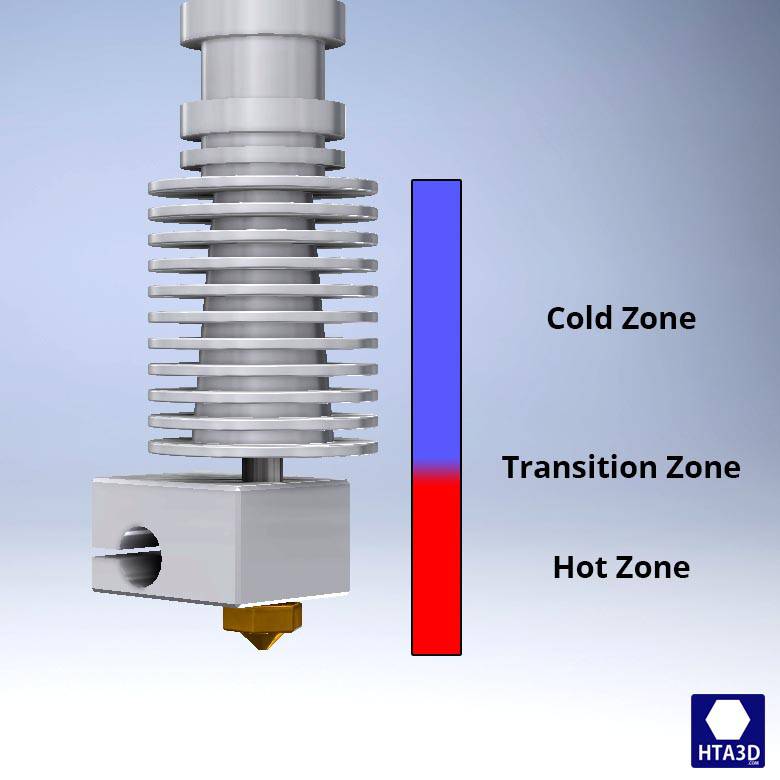

The Hotend is the element of the 3D printer which function is to melt the filament.

The filament is introduced in solid state into one end and it is extruded by the opposite end in a controlled manner.

There are many different types on the market, but they all have three zones in common that we can identify as:

- Cold End:

It is the zone in charge of keeping the balance of the temperature, it avoids that the heat spreads all over the hotend and that it reaches the extruder.

In the current models it is composed by an aluminium heatsink with a fan. The fan must be on continuously.

- Transition Zone:

It is the zone where the change of the state of the material is performed. It is connected to the cold zone and the hot zone.

In older designs Peek was used, now stainless steel is used.

The Throat is the zone that performs the function of transition.

- Hot Zone:

It is the zone where the material ends the process of state change and it is melted completely. The filament also changes its shape in order to adapt itself to the nozzle diameter.

In this zone we can find the inferior end of the throat, the heater block (that isnt’t in contact with the filament) and the nozzle. The heater block contains a heater cartridge that provides the necessary energy to reach and keep the temperature, and a temperature sensor (termistor) that displays the temperature in this area.

Leave a Comment