3D printing as a service is one of the areas with the greatest future projection growth. This technology is more known every day and due to its advantages and the opportunities offered by its reception and implementation it is being very fast.

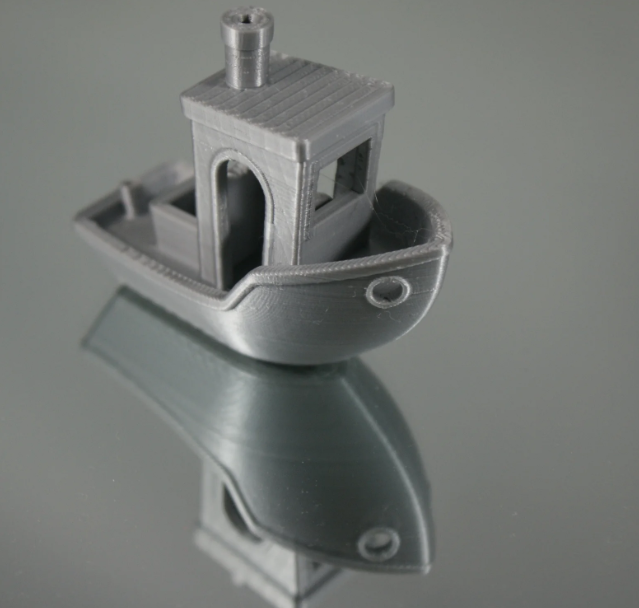

Prototyping

This is perhaps the application that first comes to mind when thinking about 3D printing, we have seen it on television, movies and other media, and, indeed, it is perhaps the most widespread application by the following features:

- It's fast, since we can have a prototype printed in a matter of hours or a few days. Other prototyping processes take much longer, usually weeks. This advantage is magnified by taking into account the number of iterations we can perform, easily a couple of iterations per week, reducing the time to have the project ready.

- Cheap, the most used material (PLA) is around € 13-20 per kg, and this is the highest cost in a 3D printing. 3D printers are also very affordable machines with a very low maintenance cost.

- Ease of making modifications, not needing auxiliary means for production such as molds or dies, making changes has no extra cost. The cost of making 2 variations of the same piece will be similar to the cost of making 2 equal pieces.

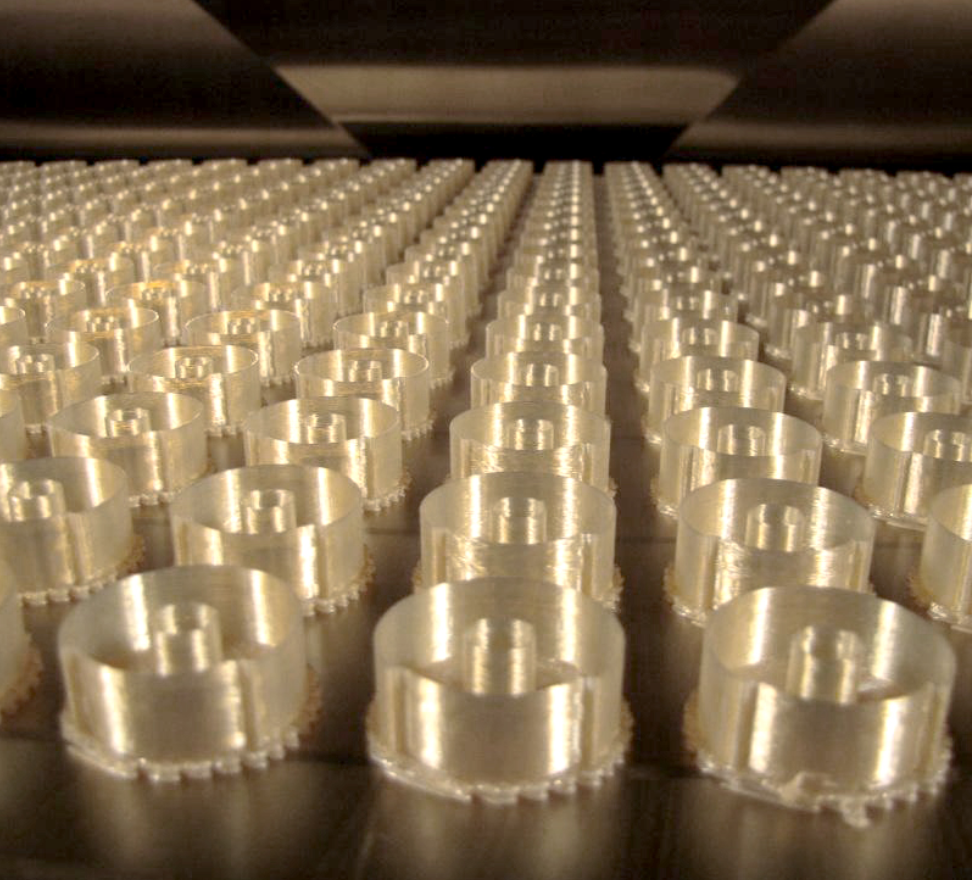

Production of small series of parts

Although the prototyping has monopolized the attention of a large part of the public on 3D printing.

It is important to know that 3D printing can be used successfully for the production of final pieces, because the changes on the design do not have extra costs, ideal in a changing world like the world in which we live, in which the appearance of a new electronic component can leave a design obsolete or outdated in a matter of weeks.

If this change involves updating the design in 3D printing, the cost will be minimal, compared to the large costs that can be involved if you do the production by injection and need new matrices.

The appearance of new materials, such as the PLA 3D850 and 3D870, as well as PETG and others, allow us to offer solutions with great quality and performance, which a few years ago could not.

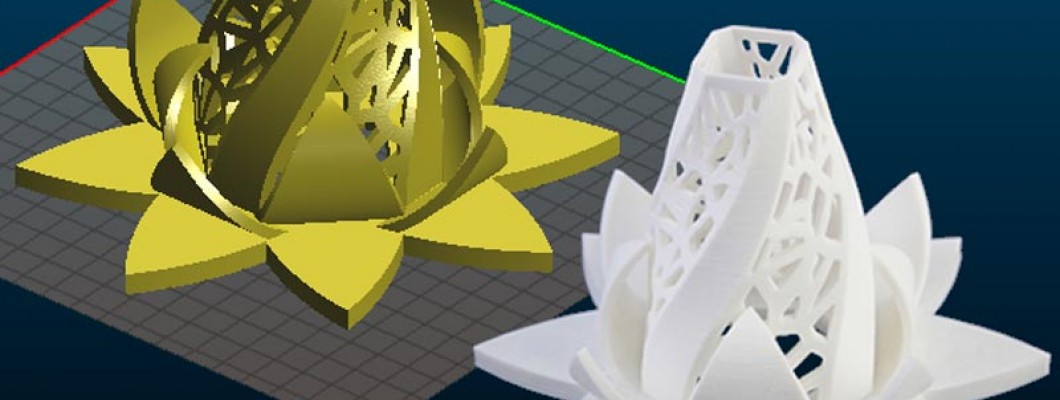

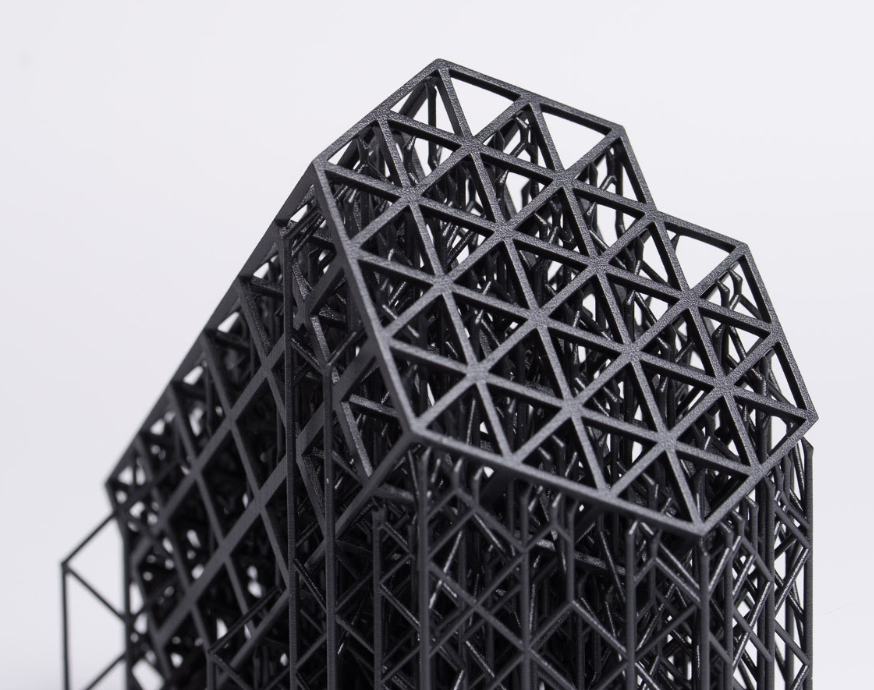

Production of parts with complex geometries, impossible by injection

3D printing is an additive manufacturing technology, in which the model is built layer by layer. It is a process diametrically opposed to conventional CNC manufacturing, which uses subtractive methods. These methods have greater limitations when making certain geometries, such as hollow pieces and thin walls. However, these geometries are easily made by 3D printing. If we compare it with the use of molds and dies, we are in a similar situation, the limitations of form are different.

Architecture

A field of application of 3D Printing, in which the 3D printing service becomes especially relevant. With 3D printing components can be produced accurately and reliably with a lot of detail, which will make the models very realistic. Compared to other manual processes that consume huge amounts of time, 3D printing produces the parts automatically.

In this field, 3D printing will not be a substitute for conventional processes, but it can be a complement that brings that plus of quality and realism.

Custom items

As the changes and iterations have hardly any extra costs, it is very easy to produce pieces with small or large differences. Letters, inscriptions, colors and shapes can be modified so that each item is different from the previous one and personalized according to the client's requirements. In this way, you can very easily have an exclusive article that only you will have.

Molds and models

3D printing complements very well with other types of manufacturing, you can 3D print a model, which will then be used as a model in the production of silicone molds. This way you can make plaster and even metal items if you make a sand mold. The possibilities offered to us are practically endless.

Limitations and inconveniences

Although the advantages and opportunities offered by 3D printing are very broad, technology, as it can not be otherwise, has its limitations:

- The production of large parts is very complex, since the printing time goes off. In addition, other inconveniences appear as problems derived from the contraction of the material.

- The materials that can be worked on are getting better and better, but they are still limited. You have to know how to adapt to these limitations to get the most out of it.

- Some geometries that may seem simple can be very complex to produce. Something as simple as a hollow sphere is very difficult to print, since it needs a very significant proportion of media, interior and exterior.

- The materials have to be thermoplastic polymers, which are inevitably affected by temperature, so they are generally bad working in circumstances of extreme heat. Each material has its softening temperature, usually between 80ºC and 100ºC, so if you need a material that supports temperatures above 100ºC they are difficult to find in 3D printing.

- Tolerances less precise than, for example, by CNC, due to the very nature of the material, the material solidifies layer by layer, so this contraction is not always distributed evenly in the piece. This, together with the limitations on the flow control of 3D printing and variations in material diameter, prevents offering tolerances as can be offered with a CNC machine.

Buy a printer or outsource 3D printing?

It is a good question, and the answer will depend on each specific case.

You are interested in hiring the 3D printing service when:

- You do not want to face the expenses and complications of having one, several or many 3D printers. If, for example, you have a production of parts for which you would need 10 or 100 3D printers, you will need an enabled space, qualified personnel to operate with them and different costs, such as maintenance, updating and replacement costs, etc. If you subcontract the service you will forget all this, we will take care of meeting the deadlines and keeping the machines in perfect condition.

- You have great variations of sale and production. For example, you have a niche product that sells very well at Christmas, but not the rest of the year. Are you interested in having the necessary infrastructure all year? Probably not.

- Your project or company is growing and you want to focus on other areas such as sales and distribution. In this case you can simplify things.

In addition, you will have other advantages, such as technical advice and a specialized team that will offer you the best in 3D printing.

You can also have a mixed production and hire the 3D printing service for production peaks or to cover other needs, such as new materials and parts that are out of the ordinary, etc.

Are you interested in trying our 3D printing service? Please do not hesitate to contact us, it is probably cheaper than you think and the results will surprise you.

Leave a Comment