- Stock: 99

- Model: P3STEEL-DUAL

Available Options

Free shipping to mainland Spain, cheap to other destinations.

Pay in three interest-free installments with PayPal. 0% APR.

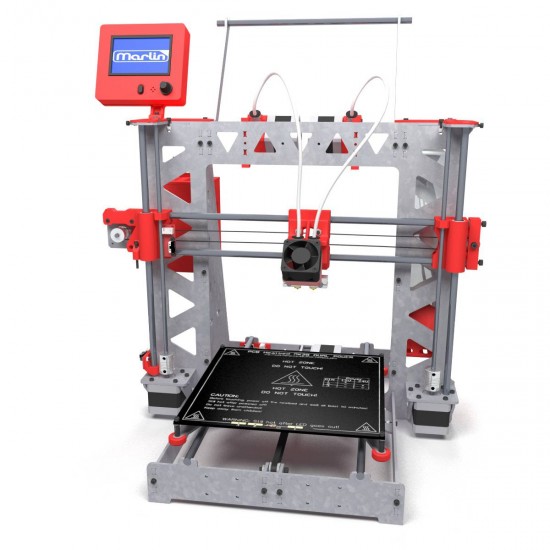

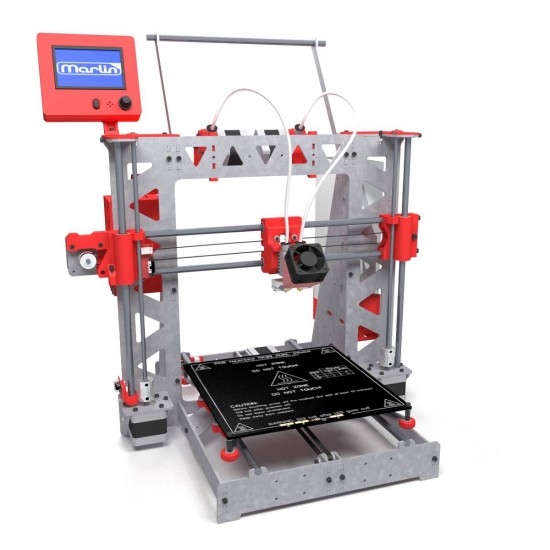

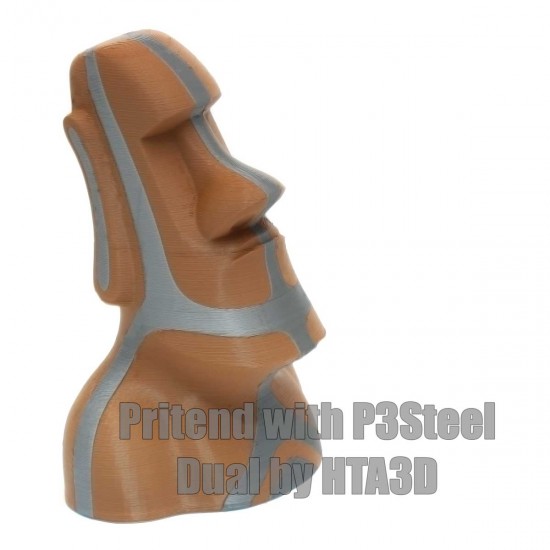

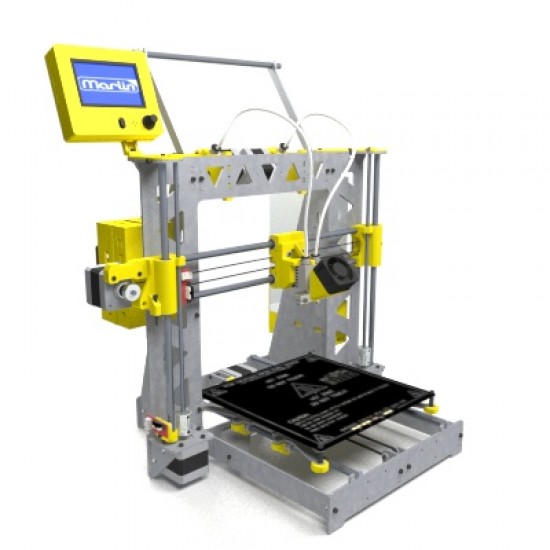

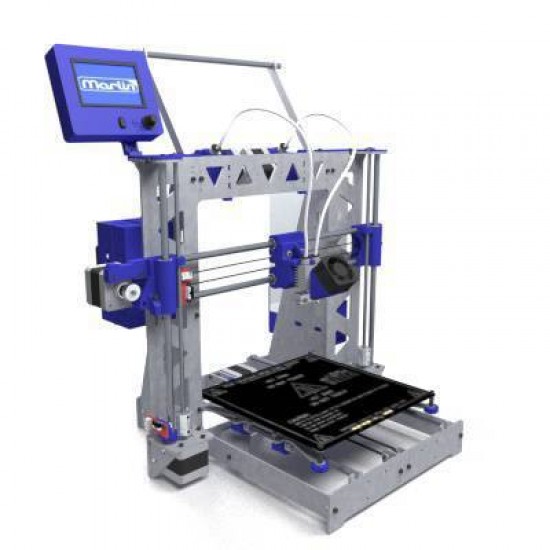

DUAL P3STEEL by HTA3D – DIY

This kit contains the necessary parts to build the P3STEEL redesigned by HTA3D.

Due to its performance this is the model we use for our printings.

Features:

Printing volume: 200x200x200 (XYZ).

Maximum printing speed recommended: 160x160x3 mm/s.

Compatible with all 1.75mm filaments that print under 300ºC (or 245ºC if you prefer the extruder with teflon).

Resolution: 6,25 microns in X and Y, 0.125 microns in Z.

Compatibility with nozzles from 0.2mm to 1mm (0.20 0.25 0.30 0.35

0.40 0.50 0.60 0.80 and 1.00). We recommend intermediate values if it

is your first 3d printer (0.4 is ideal).

Improvements:

General:

Every axis has its endstop clearly indentified in its position. In addition, we use endstops with LED indicator, already welded and wired.

Cable holder chain for X axis.

F624zz bearings for the X and Y axis and tensioners.

Assembly instructions detailed on video (see tab "Assembly Tutorial").

Error Corrections:

No dead zones, such as the upper side of X axis generated in others versions

Fixed the problem with the nut that collided Y motor

Fixed the problem for which the belt of the Y axis stayed bad alligned and generated unwanted tensions

Changed the parts that fastened the Y carriage bearings for others that don't deform the bearings, they can't lave their position and they are easier to install.

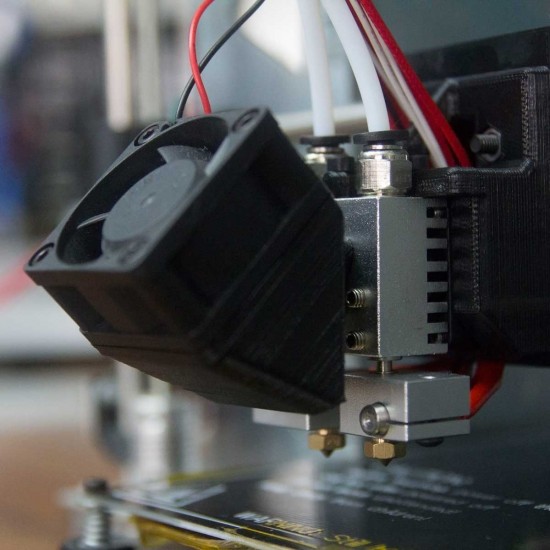

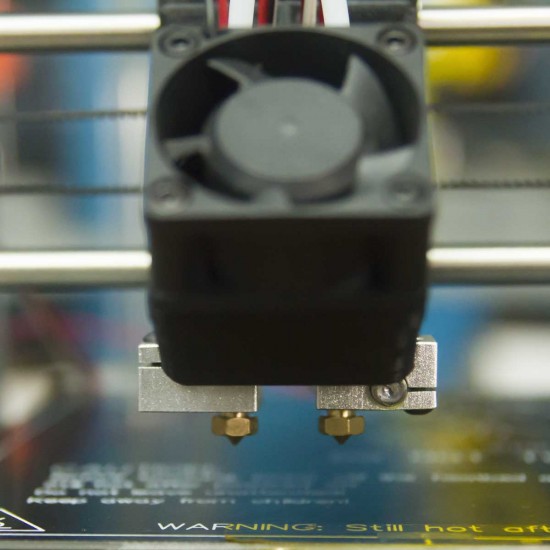

HTA3D Dual Extruder:

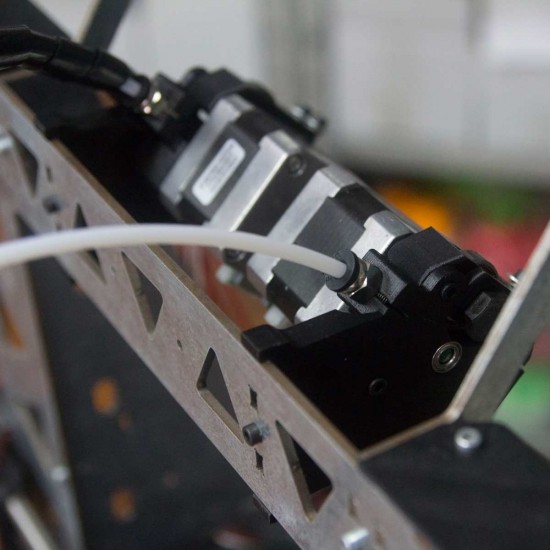

Mk8 Pulley, made of stainless steel, provides a very accurate and powerful extrusion

Duañ Hotend V6, ensures greater control over temperature, as well as outstanding performance

Its location provides us a great advantage in Z and minimizes the oscillations

Layer fan included

Recommended retraction: from 3mm to 30mm/s

Y Carriage lightened:

Lightened the weight of this part, decreasing the weight in 300 grams.

The Heatbed is now easily calibrated using only one hand, and thanks to the self locking nuts it will stay calibrated during many printings

Filament support integrated:

This component is very important as it has a considerable impact on the print quality. Our system includes bearings 608ZZ, which avoids filament jerks and provides a fluid filament supply from start to finish

Electronic Box:

The electronic is protected from accidental contact, and well refrigerated thanks to a 6cm diameter fan.

Case for the LCD (LCD included):

Forget about having the printer attached to the computer, you will print independently and will have a total control over the printing.

Protector for the power supply terminals, with switch:

- We have taken care of every detail of this kit, so with

this simple component you can turn off and on the printer easily and

safely.

Dimensions and weight of the 3D Printer:

The weight of the printer may vary depending on the chosen components and extras. For a basic configuration the weight is approximately 12 kg.

The outer dimension of the printer is approximately: 47x38x60 cm (having into account a standar coil of filament). We have to bear in mind also that the Y axis (38cm) moves, so it needs some space at the rear and at the front of the printer.

94% Customers recommend this product

- 5 Awesome87.5%

- 4 Great6.25%

- 3 Average6.25%

- 2 Bad0%

- 1 Poor0%

Reviews Over DUAL P3STEEL by HTA3D - DIY Kit

- (5)

Total Reviews (16)

click here write review to add review for this product.

Excelente calidad de todos los componentes y materiales.

En mi caso que compre desde Argentina me llegó todo en perfecto estado.

El servicio de atención es muy bueno inclusive su servicio de post venta.

Totalmente recomendable.

Report this review.

Composition:

Galvanized steel frame (3mm)

Threaded and Smooth Rod Kit

Printed Parts

Electronic

Movement Kit

Nuts and Bolts Kit

Available Options

1. Galvanized steel frame (3mm):

Laser cutting of a high-quality galvanized steel sheet, according to our redesign, with the following improvements:

Dramatically lightened the Y axis carriage, in order to improve dynamic behavior.

Filament support included.

Fixed the problem with the upper left side (the extruder collided with it), and also the problem of the nut that collided with Y axis motor.

Modified the distance between the two pieces that make the Y axis tensioner, so as to hold the F624zz bearings with washers. Also, modified the hole diameter.

Y axis measures 350mm now, the extra 9mm are added on the front side.

Y axis bearing holder and Y axis belt holder are replaced by printed parts, as the metalic parts caused troubles.

2. Theaded and Smooth Rod Kit:

2x 375mm Smooth Rods – Stainless Steel

2x 350mm Smooth Rods – Stainless Steel

2x 320mm Smooth Rods – Stainless Steel

2x 300mm M5 Threaded Rods – Stainless Steel (When Z Axis: M5 is selected) / 2x 300mm T8x8 Threaded Rods – Stainless Steel (When Z Axis: Leadscrews is selected)

1x Smooth Rod for filament support

The cutting is done by hand, so that the meassure can be slightly higher (+ 1mm or similar) not lower. All rods are shipped without burr and the edges filed down properly.

3. Printed Parts:

Extruder (1,75mm):

Body

Extruder Idler

Manual advance wheel

Reinforcement

Layer fan 4020 support

Cable holder chain

X axis:

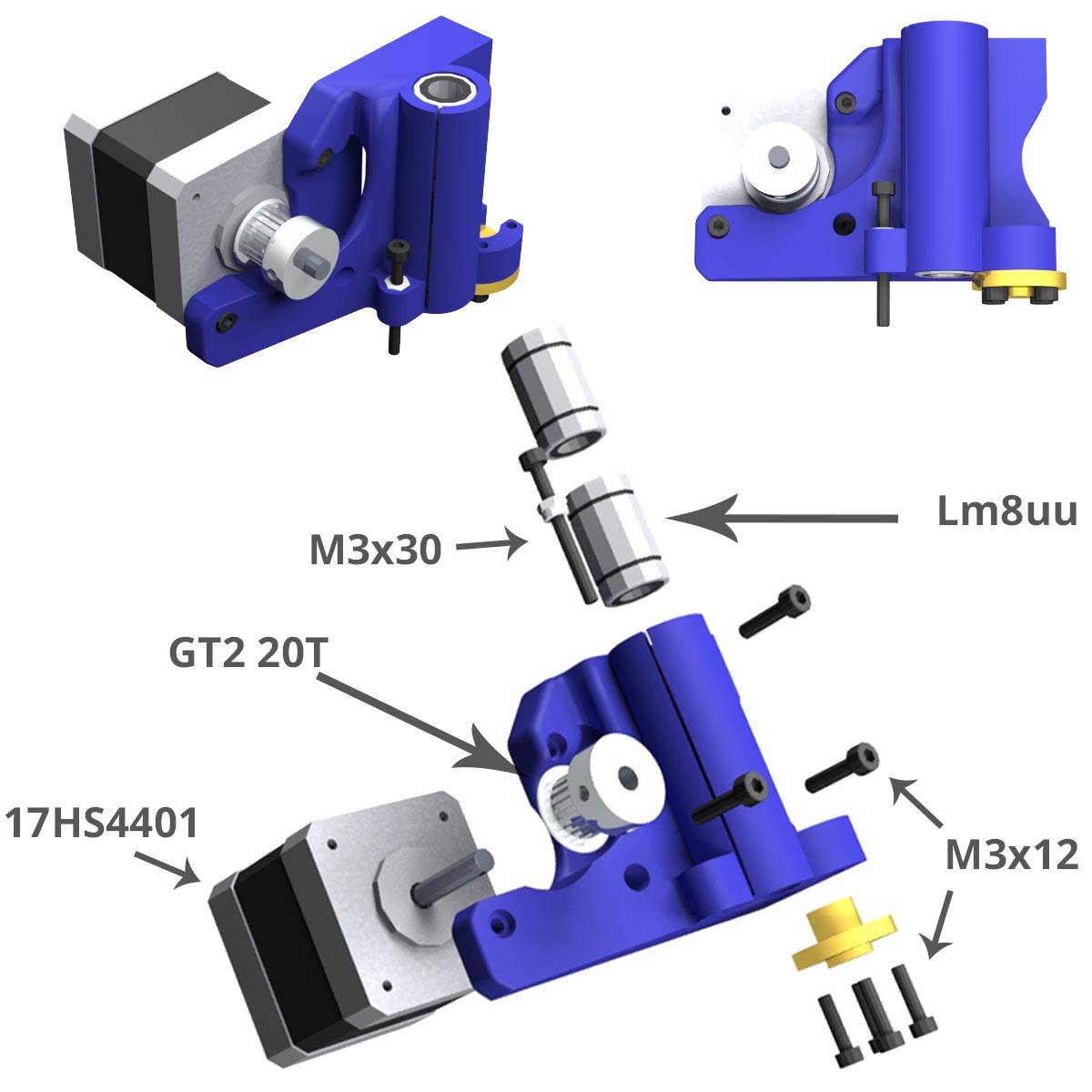

X Motor and X ilder, with tensioner for F624zz bearing

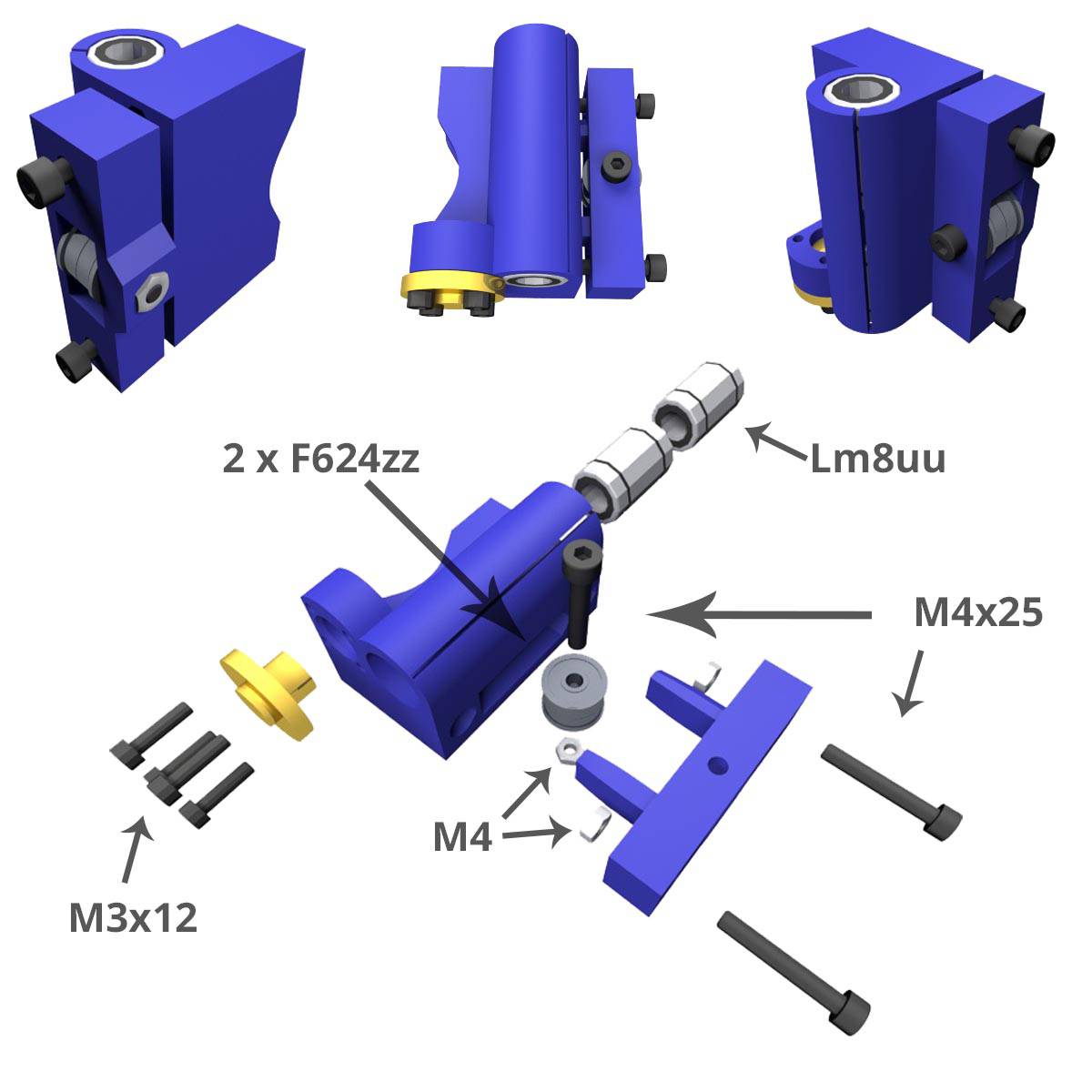

X axis carriage

X axis endstop support

Y axis:

Belt holder

Lm8uu holder

Separators for motors

Corners for calibrating the Heatbed

Y axis endstop support

Z axis:

Z Axis upper side for MR105

Z axis endstop support

Box for Ramps 1.4

LCD Case

Cover for power supply

Printed parts for a smooth running of filament

*You can choose the colour, otherwise, we will ship them randomly.

4. Electronics

Mega 2560 R3 (Compatible) 16u2

Ramps 1.4 (with aluminium heatsink)

Stepper Motor Driver DRV8825 x 4 (with heatsinks and thermal double-sided tape)

Heated Bed MK2B (12v/24v) (or the version you choose)

Termistor 100k Ω NTC 3950 (1m wire)

5x Stepper Motor Nema 17 - 17HS4401 or 3x 17HS4401 + 2x 17HS4401s-T8x8-310MM (as option)

3x Mechanical Endstop (wired)

1x Optical Endstop (for experimental filament presence sensor)

1x Fan 4020 (layer fan)

1x Fan 6010 for electronics

1x Hotend All Metal V6 equippped with ceramic heater, with thermistor, and 3010 fan. Nozzle at your choice

12v 30/33a DC Power Supply with switch, printed part, 1mm2 wire y power adapter

LCD with rotary encoder, SD reader and adapter for Ramps

Kapton Tape15mmx33m

Insulating tape resistant to high temperatures, highly recommended, as it serves to insulate the connectios (for example the Heated Bed) and to hold cables.Thermal Insulation for Heated Bed

Increases the rate of heating of the bed, reduces energy consumption, and protects the electronics

(We recommend to isolate with kapton the part in contact with the Heated Bed)50cm shrinkable 2mm2

HeatBed wires (1mm2)

Fan wires

1m protection for cables (spirals) y flanges

5. Movement Kit:

12x Linear bearings LM8UU or 12X IGUS DRYLIN® RJ4JP 01-08

4x Angular bearings F624zz (for X and Y)

1x Angular bearings 623zz for extruder)

2x Bearings Mr105zz (for Z axis when "M5 version is chosen")

2x Bearingss 608zz for the filament coil

2x Couplers Shaft 5x5mm (for Z axis when "M5 version is chosen") / 2x Couplers Shaft 5x8mm (for Z axis when "Leadscrews version is chosen")

2m Belt GT2, made of neoprene with reinforcerd fiberglass

2x GT2 Pulley, 20 teeth, aluminium

6. Nuts and Bolts Kit:

1x Mk8 extruder pulley for 1.75mm

Screws:

M3x8 - 14 units

M3x12 - 70 units

M3x16 - 7 units

M3x20 - 4 units

M3x25 - 8 units

M3x30 - 8 units + 1 fully threaded

M3x35 - 1 unit (with spring and 2 washers)

M4x6 - 4 units

M4x20 - 3 units

M4x25 - 9 units

Setscrew M3x10 - 1units

Washer:

4 x M3 DIN 9021

12 x M3 self locking

4 x M4

Nust:

61xM3 self locking

13xM3 normal

1xM4 self locking

7xM4 normal

2xM5 Nylon (Only on M5 version)

Extra:

4 x Springs for Heated Bed

Dimensions and weight of the packaging:

The weight of the kit may vary depending on the chosen components and extras. For a basic configuration the weight is approximately 12kg and the packaging dimensions from 40x40x20cm.

Files:

Frame:

DWG - v1.02 - Parts for the Y-axis motor have been modified, now the belt can be removed more easily.

Printed Parts:

STL – v1.01 - Single extruder Version

STL – v1.02 - Single extruder Version - Compatible leadscrew pieces have been added and small tolerance corrections have been done

Firmware:

Marlin 1.1.0 RC2 - Filament presence sensor disabled - loaded by default

Marlin 1.1.0 RC2 - Filament presence sensor enabled

Assembly Tutorial

New step by step tutorials:

We have prepared a new updated tutorial serie, with further information about available options. Also printable, so you don't need a display to follow the instructions:

Assembly Tutorial (Spanish with English subtitles):

Important: We recommend reading the instructions in this tab completely, in addition to following the assembly from here since we have included additional information to the videos.

Updates:

- Thermistors have now dupont connector, no soldering required.

- Stepper motors include cable connector on base. In addition, we ship them with the wires in the correct order for Ramps 1.4. So you do not have to change the order.

- Marlin updated to 1.1.0 RC 7 version:

- Improved filament change system from the LCD or using command M600

- Bed leveling function optimized, get easily a perfect first layer.

- Small bugs fixed, now more information is displayed on the LCD.

Frequently asked questions:

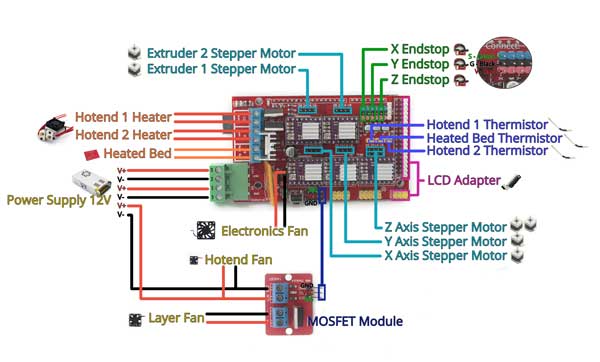

- How all fans are connected to the printer?

Fans are connected as follows:- Layer fan: connected to MOSFET module as indicated in the video

- Hotend fan: connected directly to 12V through the feeding of the module MOSFET as indicated in the video. This connection can be done as well connected to directly to the Power Supply.

- Electronics Fan: connected directly to the output of 12V in RAMPS (the connection we find down the X axis stepper driver) as shown on video. This connection can be done as well connected to directly to the Power Supply.

- The extruder motor does not move when I try to move it from the LCD.

Marlin has a protection to prevent accidental movement, so the extruder will not move with temperatures under 170°C. Try heating the hotend over this temperature and the extruder will move

Assembly drawings:

Xmotor, Leadscrews version:

X idler, Leadscrews version:

Connection Diagram of RAMPS 1.4:

Order and Orientation of the Stepper Motor wires:

Keep the colour order of the wire; the RED wire goes DOWNWARDS when connecting to the RAMPS.

Additional considerations:

- Connect limit switches as indicated in the video or scheme, an incorrect connection can damage the Mega board.