Cool Pull or Atomic Method to clean the nozzle of our 3D Printer

Cool Pull or Atomic Method is a technique to clean the nozzle. It can be done after a jam, or as a preventive cleaning after a change of material or many hours of printing.

With the Atomic Method technique, we can extract residues and/or burnt particles of filament from the nozzle that adhere to the walls of the nozzle making difficult or impossible 3D printing.

It is a simple technique to perform that does not require disassembling the hotend. So it is highly recommended for any problem related to extrusion, and always preferable to any other intervention such as changing nozzles, cleaning mechanically, etc.

To do it we will need some filament, preferably a light colour, to easily see the waste that we have removed.

This method can be done with any material, although "sticky" materials with some flexibility and resistance will be ideal, such as PLA3D850 or PETG. We recommend these materials because they are materials that stick well to the waste and are strong enough to perform the pull. In the case of PETG, its working temperature is intermediate so it will help especially if we were printing with materials that require a higher temperature than PLA, such as for cleaning an ABS jam or flexible material.

Waste can reach our nozzle by many factors, including:

- The environment where we print: dust particles that are deposited during printing on the filament.

- As part of the filament: especially in low quality filaments, these may contain impurities that favor the accumulation of dirt.

- Incorrect configuration of printing: even high quality materials degrade at high temperatures, if you use temperatures outside the range recommended by the manufacturer or if the filament remains hot without printing for a long time, the filament will be damaged and accumulate in the walls of the hotend in the form of waste.

- For the normal use of the printer: even if we only use filament of good quality it is normal that very slowly it accumulates some residues, so it may be convenient to carry out this method, even if there is no jam, as a preventive.

- It should be noted that small nozzles are more prone to accumulate waste, since the extrusion of the waste through the hole is more difficult the smaller the nozzle is.

The waste can be in the nozzle in different ways:

- Partial jam: the extruder continues working, but the material flow is insufficient. Filament waste remains stuck on the walls of the nozzle making the printing difficult. In this case, the printer can probably continue printing, but if we try to extrude material manually we will notice a resistance higher than usual, if the accumulation is large we can also notice a decrease in flow (subextrusion).

- Total jam: filament burned in the nozzle completely blocking the flow. This type of jams can be prevented many times since it can be originated from a partial jam. In many occasions it can be cleaned using this method so it is worth trying, but it will not always be possible, in which case it may be necessary to replace the nozzle.

To perform the Atomic Method we will follow the following guidelines:

- Remove the filament that was being printed.

- Introduce PLA or PETG (heating the hotend to the working temperature of the material that we are going to use).

- Make extrude some material (if possible). If it can’t extrude any material we can use a needle with a diameter less than or equal to the nozzle to help get some material out.

- Cool the hotend at 80-110ºC depending on the material. Start with low temperatures, if the material breaks without bringing out the waste try again with a slightly higher temperature.

- Pull the filament firmly (loosen the tension of the extruder tensioner so that it allows to do this without hindrance).

Once the filament is extracted, we will see how it brings residue from the previous filament and, depending on the case, pieces of burnt filament. We recommend carrying out this operation as many times as necessary until we manage to extract the filament clean, so that no particles remain that make printing difficult.

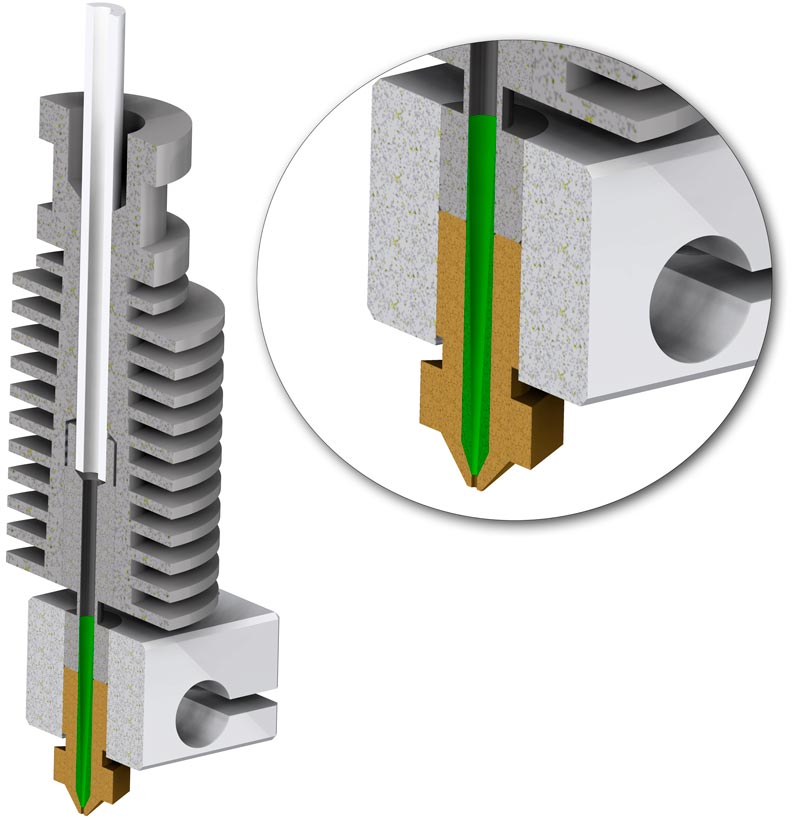

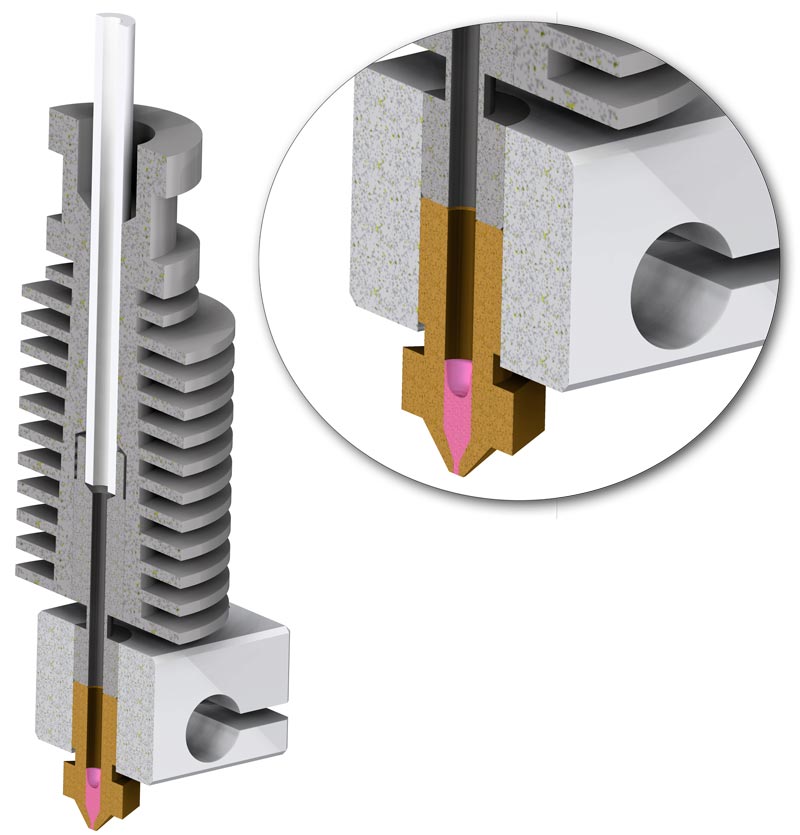

In this image you can see different cleaning examples:

In this first image we can see a mixture of pieces of burnt plastic and remains of black filament of the previous printing (reflux is present). In the following images we can see the cleaning done with different degrees of dirt.

3 Comment(s)

Muy interesante, Creia que el filamento de limpieza era de nylon y habia leido que el tiron se hacia 170ºc, los resultados con mi tecnica no son muy lucidos provare con la vuestra, gracias por compartir

Una pregunta que tal los filamentos de limpieza que han salido ¿que resultado dan?\r\n\r\n¿se extruyen simplemente o se da tiron?, bueno han sido dos

Aquí no los hemos probado aún, cabe esperar que funcionen mejor, pero con PETG ya va bien, incluso con PLA se puede hacer.

Leave a Comment