Context - Origin of 3D printing

We have to go back to the 80s to talk about the origin of 3D printing. In these years this technology was born and the first patents emerged.

As it is a new technology and is protected by patents, it is very far from the general public, reserved for large companies and organizations.

2005 the year everything changed

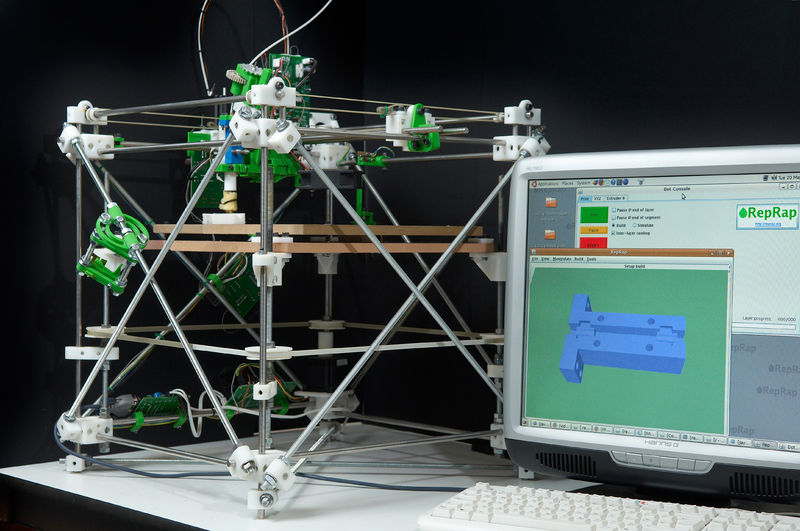

The RepRap project founded by Dr. Adrian Bowyer at the University of Bath is born, and 3D printing becomes accessible to everyone.

This happens just 20 years after the development of patents, when they expire and are released.

Although the technology is "in its infancy" this moment is the starting gun for current technology.

In 2008 the Darwin printer was born, the first with the ability to self-replicate. And in the following years, models appear, each time with better performance, and mounting kits.

Two different approaches. Open source or patent technology

It must be recognized that thanks to the development of patents the birth of 3D printing. When these were released, 3D printing became completely popular, becoming available to everyone and assuming a spectacular increase in the use of this technology.

Are patents bad because they slow down the development of a technology?

In no way, they favor companies to recover their investment in R+D+i and obtain benefits, which encourages the development of technologies

Is open source better or worse than proprietary design (protected by patents or industrial secret)?

Perhaps each technology is different, but 3D printing has shown us that open source offers us these advantages:

- Very fast development of improvements.

- Drop in prices.

- Creation of communities, blogs, forums, YouTube channels, etc.

- Birth of a multitude of companies that contribute their part to this technology.

And we must recognize these disadvantages:

- Companies that invest in R+D+ i are often less successful than companies that simply copy the development of others.

- Among all this, products and designs with very poor quality are generated that try to mix with the rest.

Is it ethical for a company to rely on the open source design of others, and the community, to create proprietary hardware and software?

It is one of the biggest criticisms of certain companies that have relied on acquired knowledge and launched products and software without sharing the code, or delaying the publication of the code as long as possible.

All this has caused a drift towards partially proprietary models, leaving open source aside. That is why the emergence and growth of this type of projects is such good news from our point of view, capable of standing up to the development generated by companies that do not release their designs.

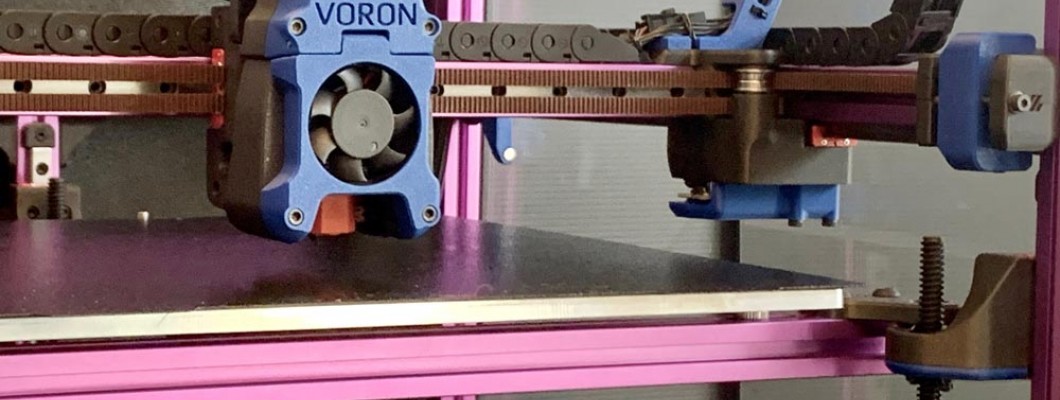

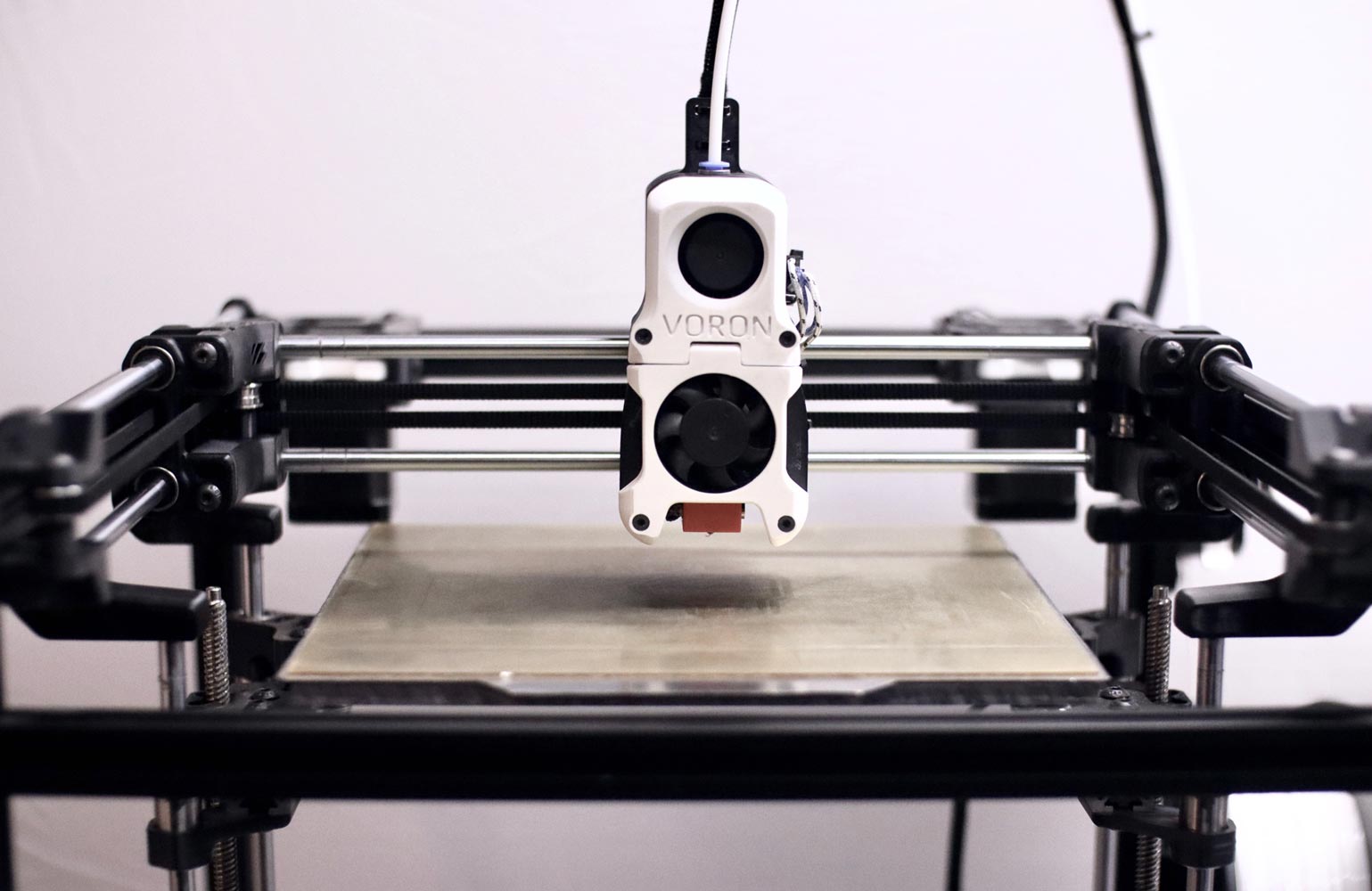

Voron design - A new look at open source in 3D printing

"The original goal of the VORON project, back in 2015, was to create a no-compromise 3D printer that was fun to assemble and a joy to use. It had to be quiet, clean, pretty, and continue to operate 24 hours a day without requiring constant fiddling. In short a true home micro-manufacturing machine without a hefty price tag. It took over a year in development, with every part being redesigned, stress tested and optimized. Shortly after the release a vibrant community formed around the project and continues to grow today. This community is part of what makes VORON such a special experience.

What was once a one-person operation has grown into a small tight-knit group of engineers united under a common design ethos. We're dedicated to creating production-quality printers you can assemble in your kitchen. It's this passion and dedication that drive us to push the boundaries just a little further. We build space shuttles with gardening tools so anyone can have a space shuttle of their own.

Welcome to VORON Design"

This new approach adapts to what a person expects from a 3D printer today, a true piece of high technology, with the satisfaction of being able to assemble it by yourself.

Each model of those designed has:

- Configurator, since it is not a static design, offers interesting configuration options, such as different sizes and extruders.

- Access to editable CAD parts.

- STL of the parts to print them.

- Detailed assembly manual in PDF, so that it can be printed and kept on hand during assembly.

- Photo gallery for reference.

- Buying guide with links to recommended products, as these printers are designed so that you get the parts separately, not as a kit.

The models that are available at the time of writing are::

Voron 0

The Voron Mini is a very small, high-performance 3D printer that can print very quickly and accurately. It is paneled, so it is designed to work with high temperature materials. Despite its small size, nothing is compromised in terms of performance.

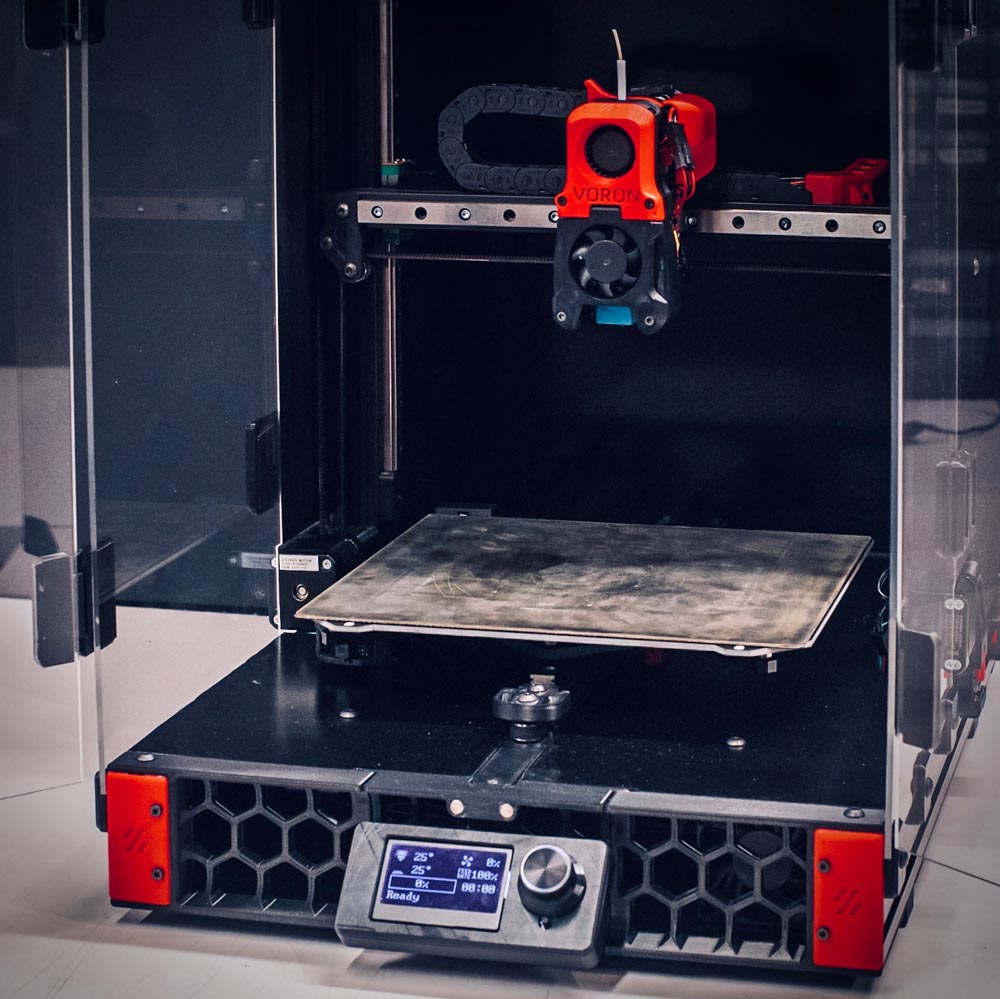

Voron Trident (1.9)

It is the most balanced model, it offers very high performance, in terms of printing speed, material compatibility, leveling of the real bed using three motors with spindles. It is easier to assemble than version 2.

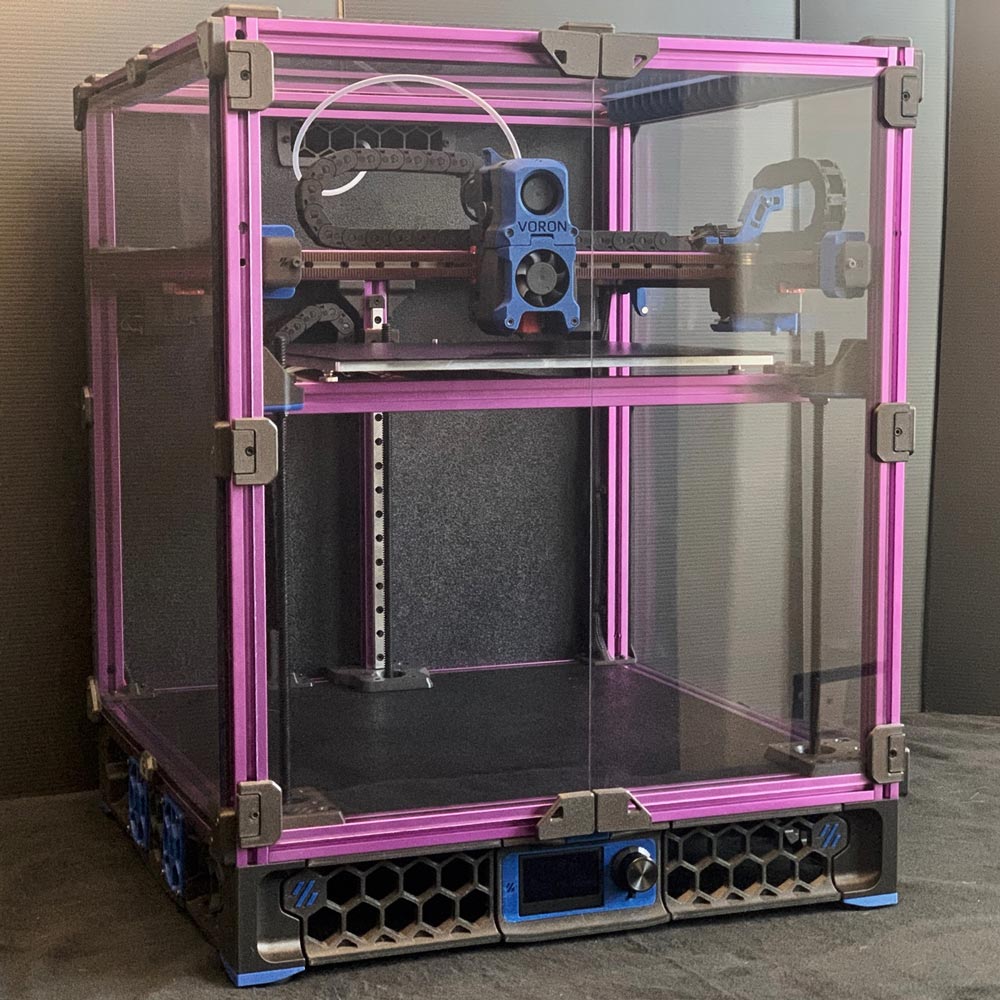

Voron 2

It is perhaps the most popular and praised model by the community.

In this model, the printing base remains immobile, fixed to the structure of the printer, so it is not affected by vibrations, nor by the weight of the piece. Being ideal for printing very large and heavy pieces.

In its place the "flying gantry" moves, the XY axes are joined to the structure by four linear guides, and the Z movement is done by 4 independent motors, thus being able to level automatically and really (without compensating). In this sense, it can be similar to a Delta printer, without the associated problems.

As a disadvantage we can point out the complexity of its assembly.

Voron Switchwire

Una impresora Core XZ. Físicamente muy similar a las impresoras donde el eje Y mueve la cama adelante y atrás. En este caso no se usan husillos para el eje Z, si no que el core XZ mueve el cabezal tanto en X como en Z, pudiendo alcanzar velocidades muy altas en este eje.

Su diseño la hace muy compacta y se puede panelar fácilmente.

Voron Legacy

A design perhaps for the nostalgic, it uses smooth rods and linear bearings.

Modifications

As if the original designs weren't enough, there are a multitude of modifications and additions for these printers, designed and maintained by the community.

These modifications include:

- Hardware modifications.

- Firmware modifications.

- Slicing modifications (Slicers).

Each modification includes detailed documentation, as well as a compatibility table, showing the models with which it is compatible.

You can find the modifications here.

Klipper firmware

It is the new software used by Voron 3D printers. It is housed in a microcomputer like the Raspberry Pi and takes advantage of the power of these processors to achieve better movement even in complex systems like the ones we find ourselves. It has many other advanced features, which we will cover in another article.

Official website

You can see the project and download all the content using this link: https://vorondesign.com/

You can also get the files from the official github: https://github.com/VoronDesign

Other Pages of interest

3DWork articles dealing with different aspects of VORON printers, such as some of the compatible boards: https://3dwork.io/?s=voron

Are these printers for everyone?

Perhaps they are excessively complex for a person unfamiliar with 3D printing, due to the complexity of its assembly. For a person who has already assembled a machine, such as another 3D printer or CNC machine, it should not present too much difficulty.

They are undoubtedly an excellent alternative for a second machine, for a first contact with 3D printing a Cartesian 3D printer with Marlin may be recommended, such as our 3DSteel V2.

Do we have kits available?

We currently have kits of printed parts, and many of the components to assemble them, you can find some here:

- Voron 2.4. Printed parts.

- Pack Voron 2.4

Leave a Comment